English

Products

Vertical Combustor TM

Vertical Stoker Type Incinerator

For perfect combustion through turning waste into fuel by SLA Combustion Method.

Features

SLA Combustion Method

Waste fed into the furnace is combusted and pyrolized by “Super Low Air-ratio” primary combustion air (λ=0.1-0.4). The new waste dropped on top of the waste layer is homogeneously dried by high temperature pyrolysis gas coming up from the below layer in order to ensure efficient waste combustion. Pyrolysis (combustable) gas is combusted completely in the upper part of the furnace by plenty amount of secondary combustion air to suppress generation of harmful substances in flue gas.

Advantages

Technical & Commercial Advantages

• No Auxiliary Fuel is Required

• No Waste Pre-treatment is Required

• Less Mechanical Troubles

• Easier to Operate

• Small Footprint

• Suitable for Power Generation

Key-features

• Efficient Drying and Pyrolysis inside furnace

• Contact ratio of Waste & Air is optimized

• Minimize Dioxins by two-stage combustion

Suitable for Various Types of Waste

Thermal Recycle Options

• Power Generation

• Hot Water Generation

• Absorption Chiller

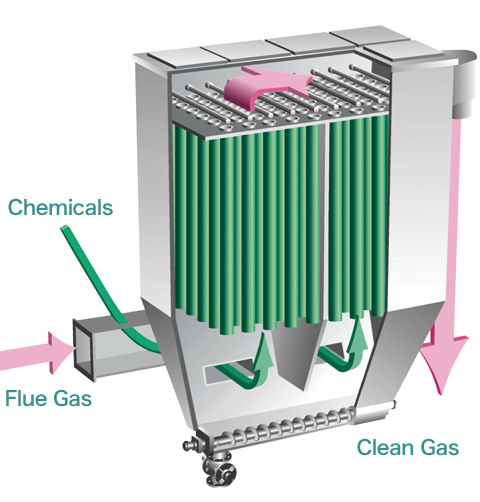

Turbo Chemical BaghouseTM

Dry-type Chemical Reaction Baghouse

Originally developed (patented) high-performance dry-type chemical reaction duct collector

Technical Features

•Pre-coated thick layers of chemicals on filter bagsimprove contact efficiency between harmful gas and chemicals for reaction and absorption

•Extended filter life due to thick layer of chemicals preventing direct contact of dust and corrosive gas

•Capable of fulfilling the EU emission standard

PLANTEC Inc.

1-6-17 Kyomachibori, Nishi-ku, Osaka 550-0003, Japan